Teacher Training in D&T: A Little Story to Begin…

- Dr Matt McLain

- Nov 28, 2025

- 4 min read

D&T Advisor, CLEAPSS

Let me tell you a tale

When I were a lad… yes, I know that sounds like something your grandad might say, but back in 1982, I started my four-year teacher training course at Middlesex Polytechnic. I signed up to become a Design teacher – or CDT, or DT, or D&T – it’s gone by many names over the years, but it’s always been about designing, making, and using tools and equipment that carry some level of risk.

To make sure we could work safely – and teach safely – we had thorough training in using all the workshop kit. The technicians who taught us were brilliant, and so were our lecturers: Dave Prest, Colin Tipping, Richard Tufnell, and the one and only John Cave. They didn’t just teach us how to use a lathe or bandsaw – they made sure we knew which machine was best for each job, why, and how to teach it confidently.

Over those four years, we learned to use every bit of equipment you’d find in a school workshop – plus some you’d only ever see in college or industry. And even though it was the 80s, we were using early CNC machines, exploring computer graphics, robotics, and 3D design on-screen for our major projects.

When we left Middlesex, we were handed a safety certificate. That piece of paper meant we’d been trained and assessed on the safe use of equipment. Employers saw that certificate as proof of competence. We stepped into our first teaching jobs with confidence that we could teach practical lessons safely.

Fast forward to today.

Things have changed.

Nowadays, very few trainee D&T teachers do a degree that includes qualified teacher status. Most come through PGCE or other routes after doing something else first. This means that, for many, training in the safe use of school workshop equipment is minimal or missing altogether. We know this because we talk to them on the Helpline and meet them on training courses – health and safety, and competence with equipment, aren’t always prioritised during their training.

But here’s the thing. Under the Health and Safety at Work Act, it’s the employer’s responsibility to keep staff – and anyone else affected by their work – as safe as is reasonably practicable. So, employers need to be confident their staff are competent to use hazardous equipment or materials.

The easiest way for an employer to do this is to appoint someone who’s completed recognised training. Alternatively, they can appoint someone who can be trained – but this takes time, which can delay them actually teaching in a D&T workshop or food room, because they shouldn’t use the kit until they’re trained.

It gets more complicated. In many secondary schools in England, Local Authorities aren’t the employer anymore – Academy Trusts are. Each Trust sets its own appointment criteria. Some stick with LA standards that specify minimum training requirements, but others don’t. There’s no common approach in England, though Wales, Northern Ireland, and Scotland tend to be more consistent.

So, here’s the crux of it.

What’s the legal position for a trainee or early career teacher who’s expected to teach a practical D&T lesson in a workshop?

Before anyone does something that carries risk, there must be a risk assessment in place, with control measures identified. These follow the hierarchy of control:

Elimination – remove the hazard altogether.

Substitution – replace it with something less hazardous.

Engineering controls – isolate or guard the hazard (like LEV for dust, or machine guards).

Administrative controls – safe working procedures, supervision, signage, training.

PPE – only used when other measures aren’t enough.

For example, if a lesson requires a certain tool or machine, the employer should first check if it can be eliminated or substituted. If not, they look at engineering controls: lockable cupboards, isolators on machines, teacher-controlled power keys, or clamps to hold materials securely.

Then come administrative controls, like:

Ensuring the teacher has completed a recognised training course covering that equipment.

In Food, having up-to-date food hygiene training.

Providing supervision by someone competent.

Giving access to model risk assessments and guidance (like those from CLEAPSS).

And of course, if these controls aren’t in place, the activity simply shouldn’t happen.

PPE is a last resort – it only protects the wearer and doesn’t make the activity safe, so it shouldn’t be relied upon in teaching situations.

The reality right now?

Many newly qualified teachers find themselves starting their D&T careers with little or no training in safe workshop practice. This puts them – and their schools – in a tricky and potentially dangerous position.

At CLEAPSS, we’re concerned that some ITT providers don’t seem to realise how vital this training is. We’ve even been asked if we can deliver last-minute training in the summer term before trainees finish their course – something that’s not appropriate and in practice not possible at short notice.

So, how do we fix this?

Training providers need to plan how their trainees will get timely Health & Safety training.

Trainees must understand they need this training before supervising practical work with hazardous tools or materials.

Employers must ensure staff can access appropriate training before teaching practical lessons.

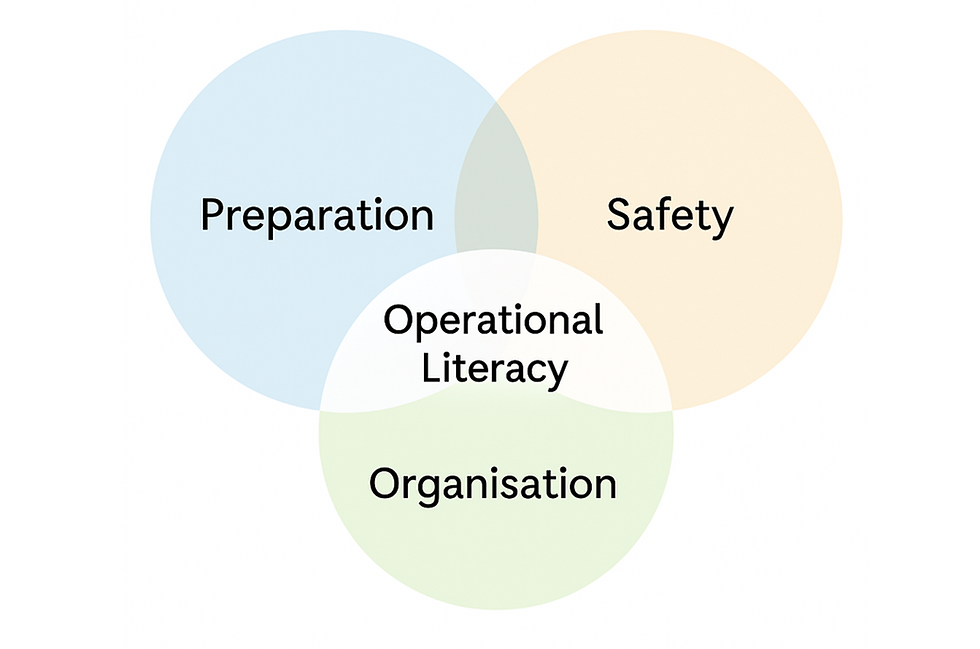

Here at CLEAPSS, we offer a wealth of online resources, from 200+ Model Risk Assessments, guides, and videos, to online and face-to-face training for teachers and technicians focusing of effective management of risks. We’ve developed a free online course for members, with short videos and exercises explaining what systems should be in place before tackling hazardous activities in D&T. You can find it all on our website.

If you have questions about any of this, don’t hesitate to get in touch via the CLEAPSS Helpline for D&T and Art & Design. We’re here to help you keep practical work inspiring – and safe.

As a current PhD student balancing my research with a part-time role at Academic Editors, I found your story on Teacher Training in D&T really relatable. During my college days, I faced a lot of challenges navigating academic requirements and deadlines, which made me deeply conscious about my studies and the support systems around me. Now, assisting students in their academic work, especially in areas like manuscript editing, has become a way for me to help others avoid the same struggles I went through. Reading about the thoughtful approach to teacher training reminded me how foundational guidance and structured support can transform both teaching and learning experiences.